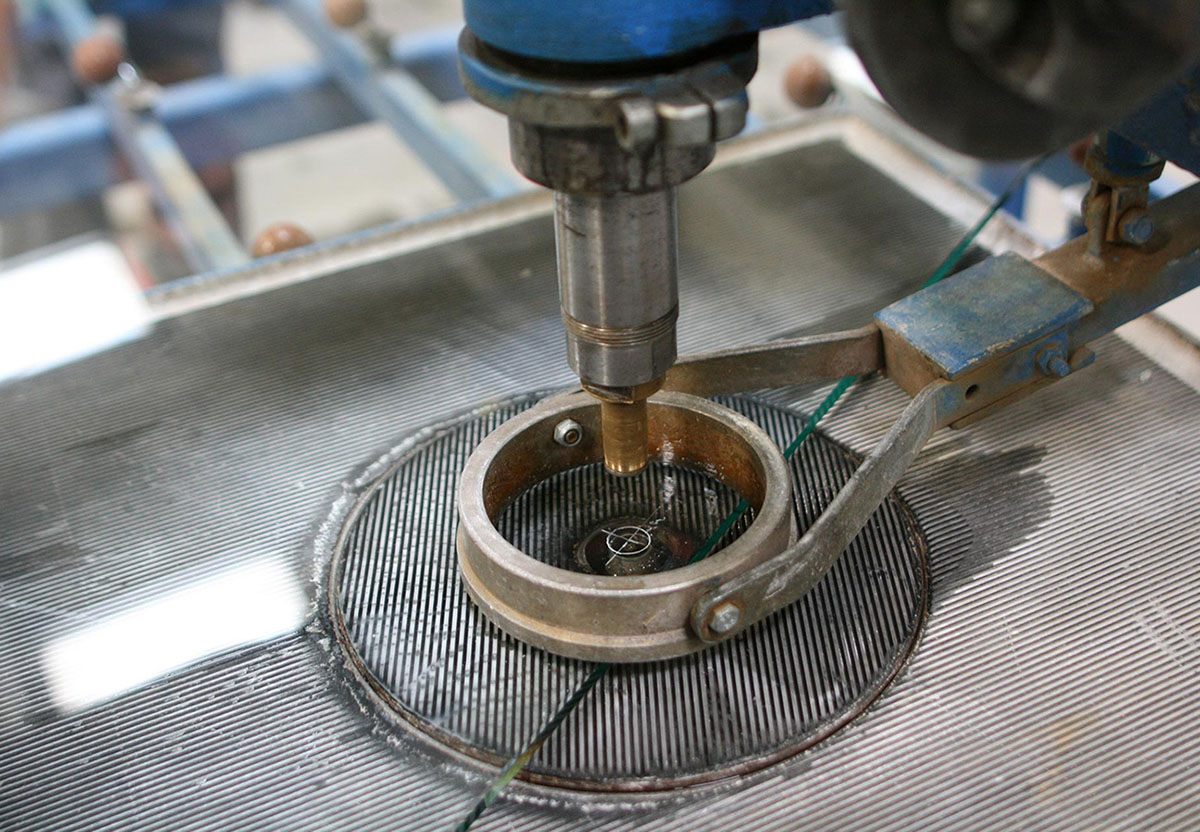

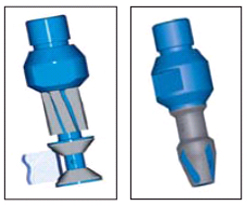

The glass is drilled by two diamond crowned drill heads opposite each other.

Using a rotating motion, first the lower/rear head drills up to half of the glass thickness, followed by the upper/front head, which, starting from the opposite side, finishes the hole and knocks out the resulting piece of cut-out glass “coin”. The tubular drill bits are cooled with water. At CE Glass we can drill with manual horizontal drilling machines and with vertical automatic drilling machines.

| Drilling machines | SULAK VTS02F | DRILLING, COUNTERSINKING |

| DAD 1000/NC | DRILLING, COUNTERSINKING | |

| GlasMas | DRILLING, COUNTERSINKING | |

| Suntech SLZ 225 | DRILLING, COUNTERSINKING |

CE Glass machines

| Process | Thinkness | Minimum size glass |

Maximum size glass |

Max weight (kg) |

Comment | |||

|---|---|---|---|---|---|---|---|---|

| Min | Max | |||||||

| Drilling | 3 | 19 | 100 | 100 | 2400 | 4800 | 600 | Minimum diameter at big glasses 25 |

| Hinge cut Interior cutout | 3 | 19 | 100 | 100 | 2500 2400 |

4500 4800 |

600 | (another machine) |

CE Glass maximum PROCESSABLE dimensions

There are some limitations regarding drilling in terms of dimensions, hole arrangements ( distance between holes, dimension from the edge of the glass and the corners of the glass). These restrictions are defined in EN12150-1.

Essentially, the following constraints need to be kept in mind:

- The diameter of the hole should not be less than the thickness of the glass.

- The shorter edge of the drilled glass should not be less than eight times the glass thickness.

- The distance between the holes, and the distance of the holes from the edge of the glass should not be less than twice the glass thickness.

- For sharp angles, the distance between the tip of the corner and the edge of the hole should be min. six times the glass thickness.

- For rounded glass corners, the distance between the assumed tip of the rounded corner and the edge of the hole should be min. four times the glass thickness.

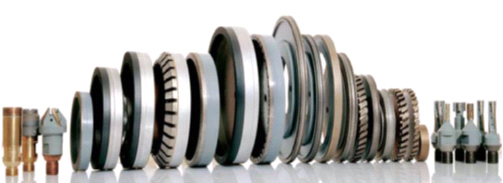

If the hole is closer than the aforesaid to the edge of the glass, the "opening" of the hole may be used, but only in the case where the notching between the edge of the hole leading to the edge of the glass is not shorter than 5mm, and not longer than twice the glass thickness. If two holes are positioned closer than the above, use the recommended "lóversenypálya" cutout instead of the holes (see Cutouts Interior cutouts). Holes can also be placed on the edge of the glass. These are called semi-holes, and the restrictions for their dimensions are the same as the restrictions for the holes. In addition to the above restrictions, the tempering of drilled glasses has separate - based on experience – limitations (see: Tempering Tempering conditions). Usually the role of the holes are to secure a place for the fixings or hinges.. During the fixing of the glass and even during intended usage, the tension in the glass can increase around these points, which can lead to glass breakage. In accordance with the limitations of tempering drilled glasses, CE GLASS recommends the tempering of such glass lites, reducing the risk of glass breakage! Dimensional tolerances for the diameter of the hole: For a diameter of 3-20 mm, the tolerance is ± 1 mm, For a diameter of 20-80 mm, the tolerance is ± 2 mm. Dimensional tolerances for the hole position: When measuring the location of the holes, one corner of the glass must be selected as the point of start, then, along imaginary perpendicular lines measure the distance of the center of all the holes from the chosen starting point. For glass with a maximum length of 2000 mm, the tolerance is ± 2,5 mm, For glass with a maximum length of 3000 mm, the tolerance is ± 3 mm, For glass with more than 3000 mm length, the tolerance is ± 4 mm. Above 12 mm glass thickness the tolerances increase by 1 mm. Countersinking may be performed on the holes created by the drill heads, in accordance with the client’s wishes.

Other operations can be performed on the inner arches of the hole, depending on whether the specific tool for the particular machining can fit into the hole.

Certain operations can only be carried out on holes which are classified as cutouts. By dimensions: - underneath ø60 mm the “holes” are treated as holes, - above ø60 mm the “holes” are treated as cutout. For example: Polishing the inside of the hole can be made only if d=60mm, so the tool can only fit into holes with the size of a cutout. Holes over ø60 mm are shaped differently than drilling, with other tools and machines (see Cutouts).